Sentry Car: Modular Mechatronic Platform

Multi-Protocol Hardware Orchestration & Robotics

Arduino

Raspberry Pi

SolidWorks

Python

Xbee

An Arduino-based robotic chassis featuring Xbee-driven remote control and Raspberry Pi computer vision targeting.

The Engineering Deep Dive

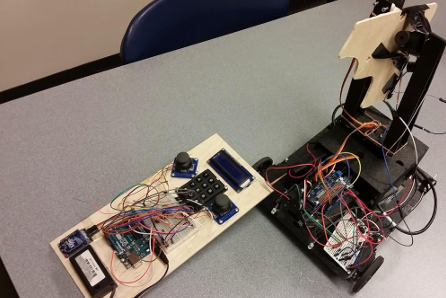

The Sentry Car was an exercise in building a robust, modular robotic ecosystem. The system architecture is split into three tiers: a Master Controller (Handheld), a Master Receiver (Chassis), and a Vision Processor (Raspberry Pi 2).

On the hardware side, I used SolidWorks to create a 'loose assembly' modular chassis, allowing for rapid 3D-printed iterations. The communication stack utilizes I2C for local sensor data and Serial-over-Xbee (19200 baud) for long-range remote operation. To handle the robotic control, I implemented artificial counters and conditional variable changes to prevent the receiving Arduino from being overwhelmed by the high-speed data stream.

The vision system uses a Raspberry Pi running OpenCV to perform real-time color thresholding. By sub-windowing the image into high-density pixel 'cells,' the system can identify and track a target, sending coordinate correction data back to the Arduino controlled servos to aim the onboard sentry in parallel with the user's movements.

The Technical Post Mortem

The biggest technical challenge was power management. During testing, the Raspberry Pi's high current draw caused frequent 'brownouts' in the shared power rail, leading to a catastrophic system crash and code corruption.

This taught me two vital engineering lessons: first, always separate logic power from motor/servo power using dedicated regulators; second, always maintain off-device backups. I recovered the project by implementing a robust serial reset logic that allowed the system to recover gracefully from power fluctuations.

Engineering Constraints

Solving for the 'Impossible' means navigating rigid physical and computational limits:

- Synchronizing high-latency Xbee data with real-time motor response.

- Managing 'brownouts' and power draw between RPi 2 and Arduino.

- Damping mechanical resonance in the 3D-printed sentry arm.