Autonomous Drone Coupler System

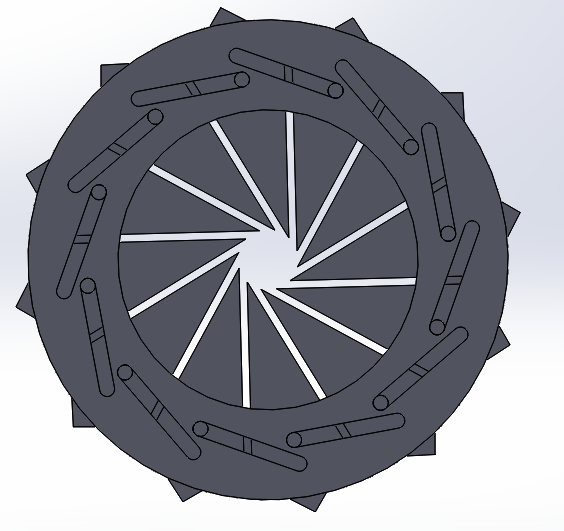

Precision Iris-Based Sensor Deployment Mechanism

SolidWorks

FEA

3D Printing

Mechatronics

Aerospace

A mechanical attachment for UAVs designed to remotely pick up and deploy sensor nodes using a high-torque iris mechanism.

The Engineering Deep Dive

Developed for the UNL NIMBUS Lab, this project involved designing a universal coupler to allow drones to autonomously place sensors in the field. I spearheaded the transition from a failing 12-leaf concept to a robust 8-leaf Iris design.

The engineering challenge was balancing the gear-ratio of the driver ring to overcome the inherent friction of 3D-printed components. By increasing part thickness from 0.125 in to 0.25 in and refining leaf and peg geometry through three core iterations, I achieved a mechanism that could withstand the high torque output of the driving servo without buckling. The final system utilized a Master/Slave Arduino architecture communicating over XBee to allow a ground operator to trigger the deployment while monitoring real-time flight telemetry.

The Technical Post Mortem

The most pivotal moment in this project was a successful failure during the 3rd iteration. A software glitch caused the servo to jerk violently, exceeding its rated torque and snapping the drive ring's pegs. Instead of just replacing the part, I performed a Failure Modes and Effects Analysis (FMEA). I redesigned the drive ring with large fillets and support arms to better distribute the moment caused by the motor. This over engineering of the stress points allowed the final version to survive the high vibration environment of a drone's undercarriage.

Engineering Constraints

Solving for the 'Impossible' means navigating rigid physical and computational limits:

- Strict payload limits: 200g to 600g depending on UAV model.

- Minimal power consumption (passive locking preferred).

- Friction management between 3D-printed ABS surfaces.