Ball Car: BB-8’s Brother

Kinetic Locomotion & Center-of-Mass Engineering

Arduino

XBee

Mechatronics

Physics Modeling

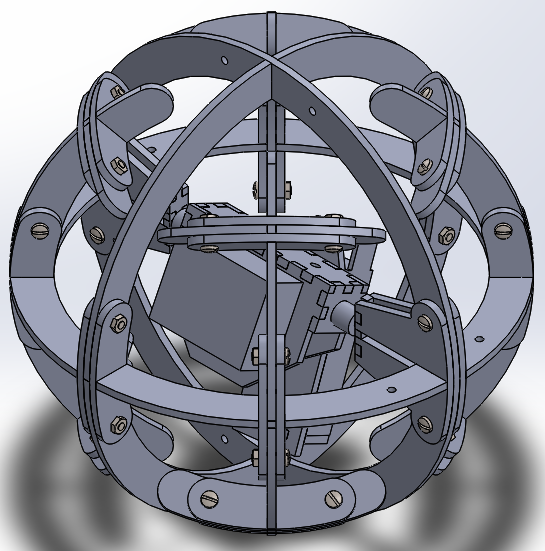

A remote-controlled rolling robot utilizing internal weight-shifting to navigate within a spherical enclosure.

The Engineering Deep Dive

Inspired by the Sphero BB-8, this project was an exploration into non-traditional locomotion. Instead of a standard drivetrain, the 'Ball Car' operates by shifting its internal Center of Mass (CoM) relative to the contact point of the outer sphere.

I designed a modular internal carriage in SolidWorks that houses two 300 RPM high-torque motors and a high-torque steering servo. The modularity was key; the entire guts of the robot can be swapped into different sized spheres depending on the terrain. The control stack uses an Arduino paired with an XBee for low latency serial communication. By mapping joystick inputs to motor RPM and servo angles, the robot can perform 360 degree maneuvers from within its own shell.

The Technical Post Mortem

One of the most interesting findings was the Cost vs. Capability parity. I built this for $149.97e xactly matching the retail price of a commercial BB-8—but with a major advantage: modularity.

Unlike a sealed consumer toy, my design allows for 'Easy Iterations.' If a motor fails or if I want to add a speaker for attitude, the internal carriage is accessible and repairable. The primary challenge moving forward was implementing an IMU (Accelerometer/Gyroscope) to automate the stabilization, reducing the manual balancing required by the driver which was very difficult.

Engineering Constraints

Solving for the 'Impossible' means navigating rigid physical and computational limits:

- Calculating precise weight distribution to shift Center of Mass (CoM).

- Managing motor torque vs. shell friction without internal slippage.

- Eliminating servo jitter to prevent erratic rolling patterns.